Back to List

Back to List

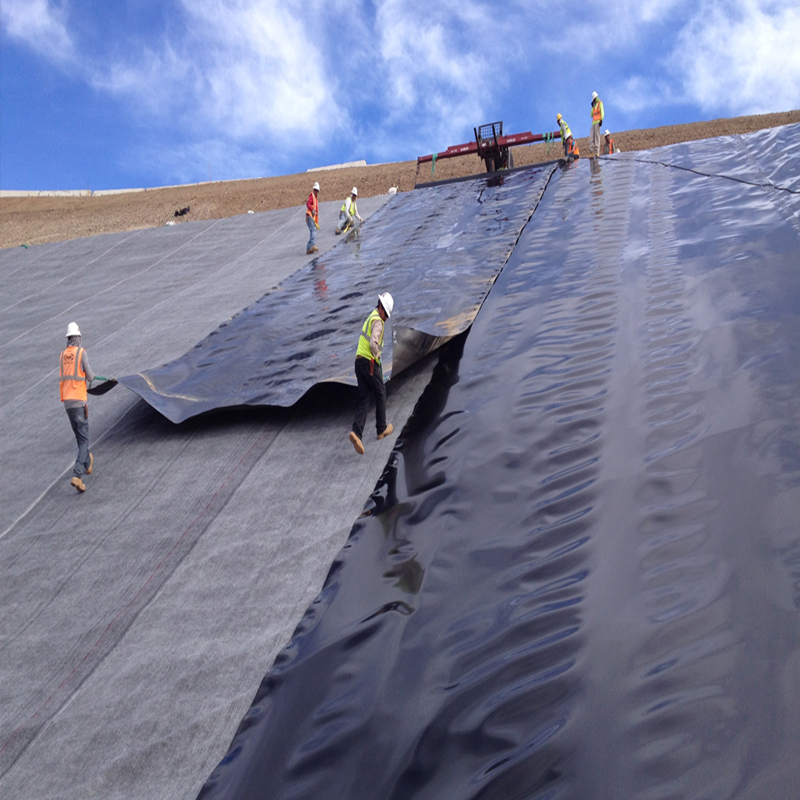

6. Geomembrane anchorage requirements

(1) During excavation, the anchorage parts shall not interfere with the soil at the bottom of the ditch.

The bottom of the ditch is flat with no loose soil.

The depth and slope of the ditch wall meet the design requirements;

(2) Do not soak in the bottom of the ditch before backfilling the anchor, and drain out the accumulated water in time;

The anchorage trench should be backfilled in time, and the soil quality of backfilled soil should meet the design requirements.

The backfill is layered with a small compactor with a compacting degree of no less than 93%.

(4) In the laying process, should avoid due to loading and unloading activities, high temperature, chemical leakage or other factors and damage geosynthetics;

Laying tools shall not destroy the normal use function of geosynthetic materials, construction machinery and equipment shall not cause obvious scratches on the geosynthetic materials, and shall not cause damage to the surface of the laid substrate;

In the laying process to adjust the overlap width of the material, do not damage the connection part, adjust the position, the installed geomembrane shall not damage the installed geomembrane;

7. If construction is to be carried out on a rainy day, it must be carried out after feasible measures have been obtained and confirmed by the supervisor and the owner's representative;

There must be construction to prevent the laying of geomemes due to strong winds blown up during sufficient temporary ballasts (sandbags).

In strong winds, geomembrane must be temporarily fixed and installation suspended.

7. Geomembrane protection

(1) People walking on geomemes shall not wear hardsoled shoes or engage in other activities that may damage geomemes;

All on-site personnel are prohibited from smoking;

(3) Can not drive on the geomembrane, can use light vehicles.

(4) In the process of operation, all equipment shall not damage the geomembrane;

(5) In areas with heavy traffic, lay a protective layer on the geomembrane;

Prevent hydrocarbon leakage or other damage to the geomembrane;

Equipped with pads large enough to prevent oil leakage from generators operating on geomemes;

(8) after the construction acceptance of geomembrane and protective layer shall be covered according to the time required.

When unfolded, the geomemes shall not be damaged, stretched or wrinkled, and the impervious surface beneath the geomemes shall be protected from damage.

8. Geomembrane welding

HDPE geomembrane outdoor construction should be carried out in weather with the above 5 temperature ℃ and less than 4 and no rain or snow wind force.

(2) Double welding lap welding welding.

Welding overlap width is 10 cm.

No impurities, such as dirt, sand (including dew), which may affect the weld quality of the lap joint surface shall be allowed.

(3) Carry out site laying experiment, determine the welding temperature and speed and other construction technology parameters.

(4) When welding, the surface of the base material should be dry, moisture content should be less than 15%.

The geomembrane surface should be wiped clean with dry gauze.

(5) Conduct sample welding experiment under the adjusted working state, test the HDPE geotechnical film sample with the welding length of 1m, use the field tear test sample, the weld is not damaged by tension, the base material cracks, and it is considered to be qualified.

After passing the field tear test, formal welding is carried out one by one by using the heat sealing machine adjusted to the working state.

Use squeeze welders to weld T-joints to repair scars and special joints.

HDPE geotechnical film at the weld should be integrated, no virtual welding or leakage welding phenomenon.

In the event of a false weld leak, the weld must be cut and the substrate repaired with a hot melt extruder so that the diameter of the cut damaged portion is greater than twice that of the damaged portion.

The width of double seam shall be 2×10 mm.

The displacement dimensions between the transverse welds shall be greater than or equal to 500mm.